In the world of footwear, comfort and safety are paramount, especially for those who work in demanding environments. That's where our Non-Slip Injection-Molded PU-sole Shoes come into play. I’ve personally witnessed how these shoes can transform a long day on your feet into a breeze. Manufactured with the highest quality materials, they’re designed not just for durability but for ensuring our customers feel secure with every step. The non-slip feature provides an added layer of stability, making them ideal for manufacturing or hospitality industries. As someone who understands the importance of reliable footwear, I can assure you that choosing our shoes means investing in employee safety and comfort. When you partner with us, you’re not just getting a product but a commitment to excellence from seasoned manufacturers. Let’s elevate the standards together with shoes that are built to last while keeping your team safe and comfortable.

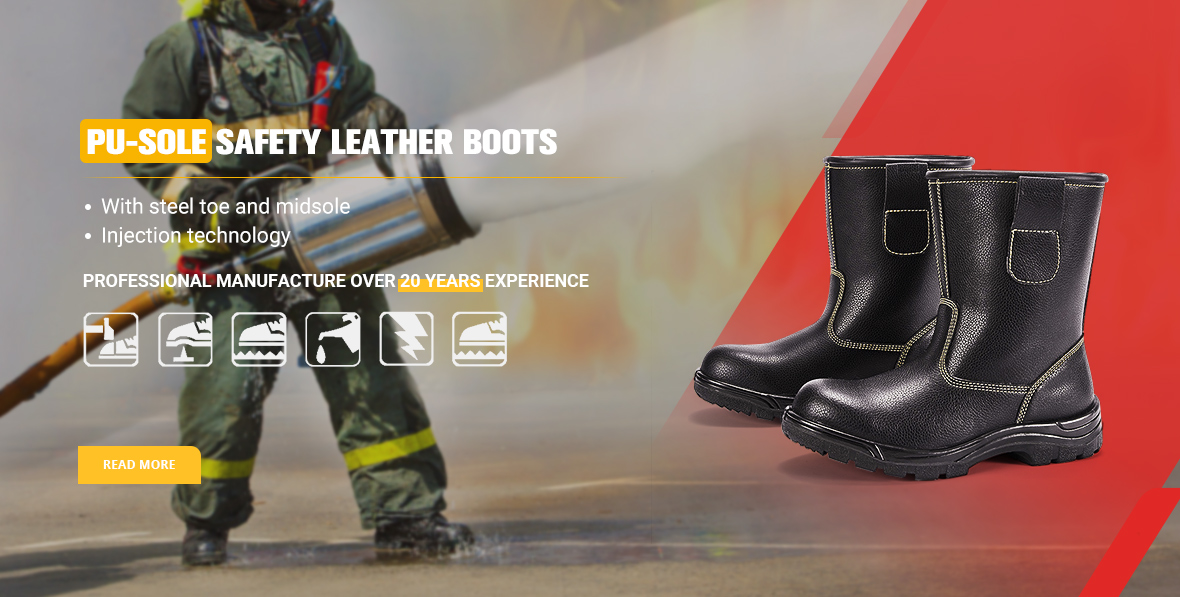

When it comes to footwear that prioritizes safety and comfort, non-slip injection-molded PU-sole shoes stand out in various industries. These shoes combine advanced manufacturing techniques with high-quality materials, ensuring durability and performance. The injection molding process allows for seamless design, providing flexibility and a light weight that enhances mobility. The PU sole offers excellent grip on a variety of surfaces, making these shoes ideal for environments where slip hazards are a concern, such as construction sites, hospitals, and food service areas. Global buyers can benefit from sourcing these specialized shoes from manufacturers dedicated to quality and innovation. By choosing non-slip PU-sole shoes, companies can significantly reduce workplace accidents, thereby enhancing employee safety and productivity. Moreover, the customization options available in design, size, and color make it easier for businesses to align their footwear with brand identity and specific operational needs. Investing in high-quality, non-slip shoes is not just a matter of compliance or safety; it’s about fostering a work environment where employees feel secure and comfortable. As demand for reliable footwear continues to grow, partnering with a capable manufacturer can ensure that buyers receive products that meet international safety standards and customer expectations, ultimately leading to a successful purchase experience.

| Model | Material | Size Range | Color Options | Min Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|

| Model A1 | PU + Rubber | 36-46 | Black, Blue, Red | 100 Pairs | 15 - 25 |

| Model B2 | PU + TPR | 38-48 | Gray, Green, Yellow | 200 Pairs | 18 - 30 |

| Model C3 | EVA + PU | 37-45 | White, Navy, Orange | 150 Pairs | 20 - 28 |

| Model D4 | PVC + Rubber | 35-43 | Brown, Black | 250 Pairs | 22 - 32 |